TouchDRO Application

The TouchDRO Android app is the core of the system—it displays the position readouts and provides the on-screen functions you use at the machine. You can download it from the Google Play Store or the Amazon Appstore.

The app connects wirelessly to a TouchDRO scale interface adapter, a compact box that reads your DRO scales and transmits position data to the tablet. Together, they give you a full-featured DRO with standard functions (bolt circles, hole patterns, sub-datums, saved zeros) plus graphical tools that traditional consoles don't offer.

TouchDRO has two operation modes:

- TouchDRO Plus — Included with current-generation TouchDRO adapters. All the features, tight hardware integration.

- TouchDRO Community — Works with DIY builds, third-party hardware, and older TouchDRO adapters.

TouchDRO Plus vs. TouchDRO Community

- TouchDRO Plus — a set of advanced features bundled with all TDA-4xx adapters and the TDK-40 kit (or standalone pre-programmed module). For kits, Plus was originally an add-on option; starting in late 2025, all kits and modules include it. If you're not sure whether you have Plus, connect the adapter and look at the app icon in the top bar—a yellow "+" means it's active.

- TouchDRO Community — the free version that works with legacy TouchDRO adapters, third-party hardware, and DIY builds. Includes core DRO functionality: readouts, bolt circles, tool offsets, sub-datums, axis summing, and Graphical View.

Plus Features

With Plus, you get additional workflow tools that save time on more involved setups:

- Photo and CAD overlays in Graphical View

- Automation—auto-advance, auto guide activation, auto tool offset direction

- Enhanced probing with auto edge detection and save-to-list

- CSV import/export for coordinates and tool libraries

Where TouchDRO Helps in the Shop

TouchDRO covers the standard DRO functions—unit/mode toggles, bolt circles, sub-datums, tool offsets, axis summing—so we won’t be doing a blow-by-blow feature comparison here. Instead, let's talk about where TouchDRO helps you get more done, and actually enjoy your time at the machine.

When building TouchDRO Plus, we focused on removing the things that pull your attention away from actually machining: extra screen taps, mental math, tedious setup steps. Fewer distractions, fewer mistakes, more time cutting.

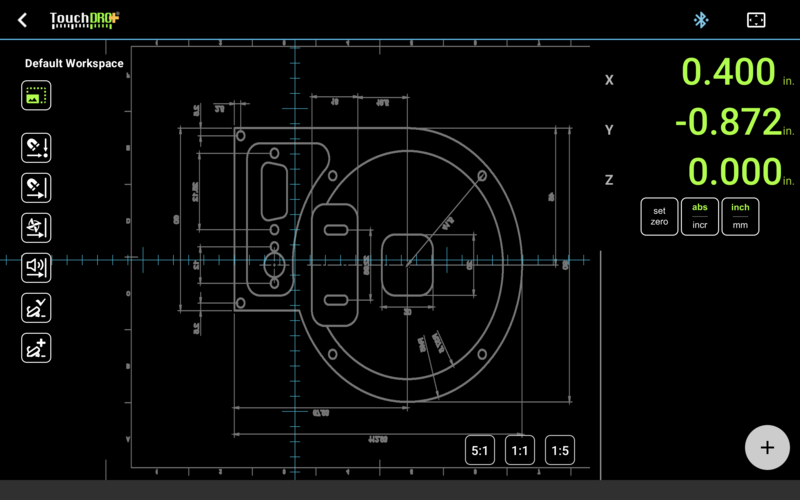

See where you are, not just the numbers

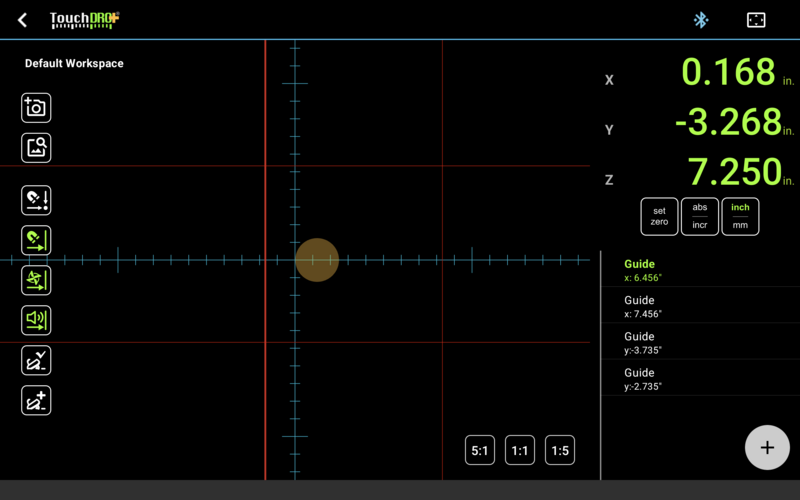

Traditional DROs show digits. TouchDRO's Graphical View shows your position on a visual workspace—guide lines, stored coordinates, cutter diameter, and your current location all on screen at once. You can see where you are relative to the part, not just read a number and do the math in your head.

And you don't have to keep tapping the screen to use it. As you move across the workspace, TouchDRO can automatically select the next coordinate as you approach it. For drilling patterns, auto-advance on quill movement steps to the next hole when you raise the quill. You stay focused on the machine, not the tablet.

One tablet, multiple machines

TouchDRO lets you set up separate machine profiles (mill, lathe, surface grinder—whatever you run) and move the same tablet between them. Each profile can also have its own layout: readout precision (0.000 vs 0.00000), which functions show up next to each axis, hidden readouts, and font size—set it up the way you like to work.

TouchDRO also has dedicated display modes for mills and lathes. For example, on a lathe, many customers add an inexpensive tachometer sensor to see spindle RPM and real-time surface speed (SFM) while they cut. On a mill, you can set cutter radius right from Graphical View—no menu diving to see where the cutting edge actually is.

Visual Layout Overlays

Graphical View is one of TouchDRO’s most useful tools, and Plus takes it further: drop in a photo or CAD image, line it up to your DRO, and machine while watching your position move over the overlay.

Use a photo as a quick guide

Sometimes you don't have a drawing—you have a part. Maybe you're making a mating bracket, matching a profile, or just trying to put holes in the same places as the original.

With TouchDRO Plus, you can snap a photo of the part and use it as a quick layout guide. Pick up a few reference points to line it up to your DRO coordinates, and TouchDRO scales and rotates the image into place. As you move the handwheels, you can see where the spindle is relative to features in the photo—useful for roughing in a shape or checking your progress. It's not a substitute for real measurement, but for "get it close" work, it beats dye and scribe.

Follow a CAD drawing on the screen

Some shapes are really “CNC parts”—rounded gussets, blended radii, profiles that would take forever to lay out by hand. If you don’t have a CNC, the old-school workaround is to print the drawing, glue it to the stock, and machine to the paper.

TouchDRO gives you a cleaner version of that idea. Export the CAD view as an image and load it into Graphical View. Calibration works the same way—pick a few reference points and you're set. Now your live position tracks across the overlay as you crank the handwheels—you can "etch-a-sketch" a profile while watching exactly where the tool is.

It’s also useful on parts with a lot of features—different hole sizes, mixed radii, that kind of thing. Even if you’ve already defined coordinates, having the overlay on screen makes it harder to lose your place.

Keep your hands on the handwheels

Pockets and slots are where a manual machine starts to feel busy. You're watching the cut, watching backlash, trying not to lose track of which edge you're heading toward. Scribe lines help—until they get wiped out by coolant and chips.

TouchDRO takes much of that mental load off. As you move toward a guide line, it can activate it automatically, set tool offset to the correct side, and beep as you approach the edge. This makes it easier to rough with a safe allowance, then come back and finish to size—no recalculating, no second-guessing which way to compensate. Same idea works on a lathe: an audible cue as you approach a thread relief helps you disengage the half-nut at the same spot every pass.

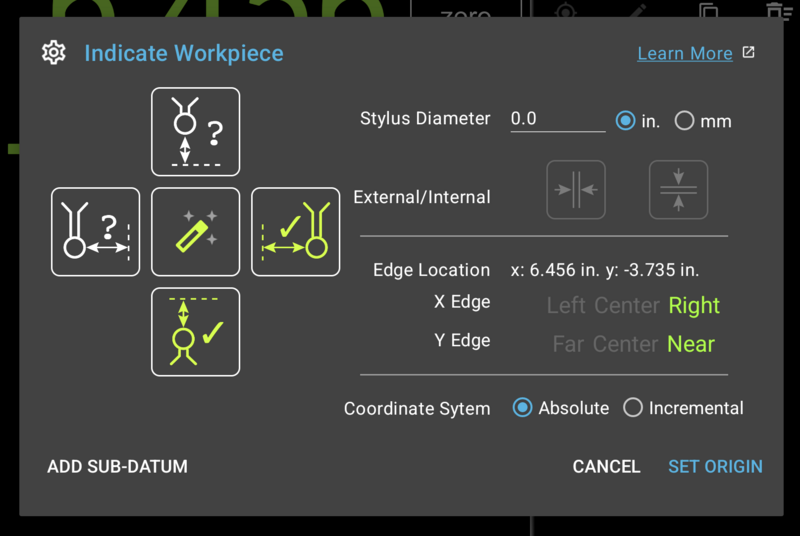

Find edges and centers without menu diving

You're probably already using an edge finder or wiggler to pick up your setups. It's not hard—it's just easy to make a mistake. The classic one: "Did I account for the tip radius, and did I add or subtract it this time?"

TouchDRO takes that kind of shop math off your plate. When you use a touch probe, it automatically figures out which edge you're picking up based on the direction you're moving. If you use a mechanical edge finder or wiggler, one tap tells TouchDRO to account for the tool diameter and set the edge.

When you're done, you can drop the result straight into your coordinate list to save the feature location. Less screen tapping, fewer chances to add when you should have subtracted, and a lot more "touch, store, move on."

Plan the job on your PC

Typing a long coordinate list on a tablet—standing at the machine—is slow, and it’s where the mistakes that scrap parts happen. With CSV import, you can build your coordinate list at a desk using Excel or Google Sheets: real keyboard, big screen, and the print or drawing right in front of you. Add descriptions, double-check the numbers, then import it into TouchDRO with a few clicks.

In a small shop, that means the next setup can be ready while the machine is still running. In a home shop, it’s the same idea: you’re comfortable, you’re not rushed, and you’re less likely to fat-finger a coordinate.

Capture and export measured coordinates

Sometimes you don't need a full CAD model—you just need the real, measured locations of a few features. With Plus, you can probe hole centers, edges, and other pickup points, save them directly into your coordinate list, and export the list as CSV.

That's useful for inspection notes, repair work, recovering a hole pattern for a mating part, or any job where the drawing is missing (or you don't fully trust it). It also avoids the “write it down, type it in later, hope you didn’t swap a sign” routine.

Feature Documentation

If you want step-by-step instructions (screens, buttons, and setup), these manual pages go into the details:

How to Get TouchDRO Plus

TouchDRO Plus is included with current-generation TouchDRO hardware—nothing extra to buy:

- DRO for Milling Machines (TDA-420) — includes touch probe/tool setter inputs (and works with most glass/magnetic scales).

- DRO for Metal Lathes (TDA-410)

- 4-Axis DIY DRO Kit (TDK-40)

- Pre-programmed module for the DIY kit

Upgrading from V2 hardware

If you have a second-generation (V2) TouchDRO adapter for glass/magnetic scales, there’s a paid firmware upgrade to V3.

DIY or third-party compatible hardware

If you built your own adapter (or you’re using third-party compatible hardware), TouchDRO’s core DRO features work the same way. TouchDRO Plus features require TouchDRO hardware that includes the Plus key.

If you have older TouchDRO hardware, there may be upgrade options (see the V2 upgrade above). If your adapter can’t be upgraded and you purchased it directly from our store, ask us about trade-in credit. Contact us.

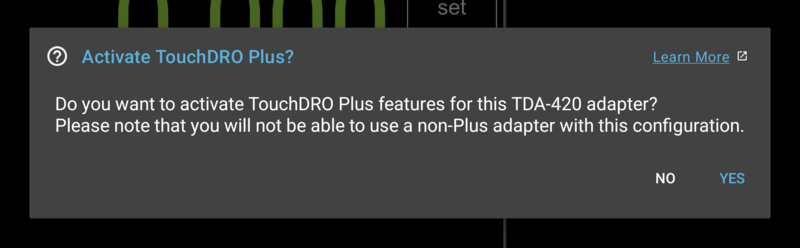

How Plus shows up in the app

Connect a Plus-enabled adapter and TouchDRO will ask if you want to enable Plus for that machine profile. Tap "Yes" and you're set—you'll see a green Plus icon, and the Plus-only controls appear where you'd expect. No subscription, no internet required.

Frequently Asked Questions

Do I need to pay extra for TouchDRO Plus?

No. TouchDRO Plus is included with current-generation TouchDRO hardware—there’s no separate purchase and no subscription.

Does TouchDRO Plus require an internet connection?

No. TouchDRO Plus is designed for an offline-first shop setup. Once you have the adapter, Plus works without Wi-Fi, without a monthly check-in, and without “phoning home.”

Which adapter do I need if I want to use a touch probe?

You’ll need the DRO for Milling Machines (TDA-420). It’s the only current adapter with touch probe inputs.

I have glass/magnetic (quadrature) scales—does the TDA-420 work with them?

Yes. The TDA-420 is designed for mills and supports optical/magnetic scales (quadrature), and it also supports select capacitive scale systems with the appropriate input converters.

If I buy a Plus-enabled adapter, can I use Plus with my existing (older/DIY/compatible) adapters too?

Not on the same machine profile. Plus features are tied to the adapter that contains the Plus key. If you plug in a non-Plus adapter, TouchDRO runs in core mode for that adapter—create a separate machine profile for each adapter you use.

Can I use TouchDRO Plus with a DIY or third-party compatible adapter?

DIY/third-party compatible adapters can run TouchDRO’s core DRO functions. TouchDRO Plus features require TouchDRO hardware that includes the built-in Plus key.

What if I have older TouchDRO hardware?

If you have a V2 TouchDRO adapter for glass/magnetic scales, there’s a paid firmware upgrade to V3. If your older TouchDRO hardware can’t be upgraded and you purchased it directly from our store, ask us about trade-in credit. Contact us.

Does the CAD/photo overlay “snap” to geometry or auto-pick points from the drawing?

No. The overlay is a visual reference that you align to your DRO using a few reference points. TouchDRO does not infer snap points or extract geometry from the image.

What data does TouchDRO Plus send back to you?

None for normal use. TouchDRO Plus is intended to run fully offline in the shop, and it doesn’t require a cloud connection or background data collection to keep working.

Ready to Get Started?

TouchDRO Plus comes with current-generation TouchDRO hardware. Connect the adapter and get to work.