What to Look For When Buying a DRO

Adding a DRO to your manual lathe or milling machine will help you machine more accurate parts, make fever mistakes, and remove stress and cognitive load from the process. But how do you know which DRO console is best for your shop?

There are hundreds of different digital readout models on the market with prices ranging from under hundred dollars to many thousands. For someone who hasn't used a DRO before, selecting the right unit can feel like a daunting task. It shouldn't be, and this article will help you understand what to look for when buying a DRO.

Most sellers readily list the features of the DRO consoles they sell but you will quickly realize that at this point even the most basic digital readout consoles provide most of the common DRO functions. It's hard to find a digital readout that doesn't offer absolute and incremental coordinate systems, imperial and metric units, bolt hole pattern functions, some stored coordinate memory, etc. At the end, many of the choices come down to personal preferences and budget but it's important to keep an eye on the following important parameters:

1. Accuracy and Resolution

A digital readout is a precision measurement device and therefore its overall accuracy and resolution are two of the most important characteristics. Accuracy and resolution mostly depend on the scale selection, which is described in depth on the Understanding DRO Scale Parameters page. What is often overlooked is the fact that the console itself can introduce errors. This happens one of two ways. First, some low-end DROs use older (and therefore less expensive) microcontrollers that can introduce rounding errors during division, for instance when using the "Center" function. Second, and more common, problem is missed pulses from the scales, which over time lead to a buildup of error. When shopping for a DRO, especially if 1 micron scales are to be used, ensure that the unit can handle the expected traversal speeds. This is most often a problem on lathes, where longitudinal movement speed can easily exceed several inches per second.

2. Ease of Use

The main reason of adding a DRO to a machine is to improve the usability of that machine. Surprisingly, DRO usability is often overlooked. In order to be easy to use, a digital readout unit needs to have intuitive and, more importantly, consistent user interface. Some low-end digital readouts have user interface and menus that seem to be randomly cobbled together in order to check a checkbox in the sales brochure. A good digital readout console should feel natural to use and shouldn't be confusing, or you will make mistakes and ruin parts. Before buying a DRO it's a good idea to download and study the user manual. Generally speaking, though, ease of use depends on the DRO display design:

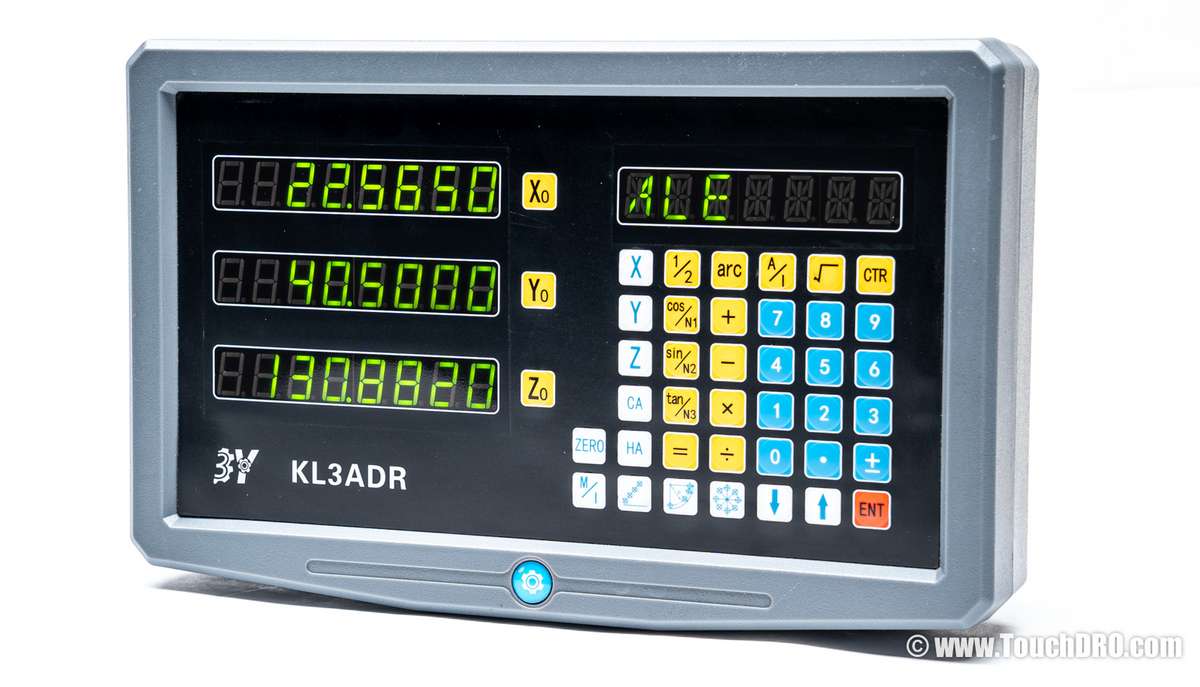

Basic 7-Segment DROs

These "old school" digital readout consoles use 7-segment LED displays with membrane or mechanical numeric keypads and haven't changed much since the 80s'. They offer a list of standard DRO functions, such as switching between inches and millimeters, absolute and incremental coordinate systems, zero set, centerline function, several hole pattern functions, tiny saved coordinate and predefined tool memories, etc. The biggest issue with these DROs is the user interface. Due to the limited number of buttons and inability to display more than a few characters of text, most operations require several key presses and deep menu systems.

Most of the well known name brands offer digital readout consoles in this market, but they are usually their lower-end models. That said, this particular market segment is dominated by the inexpensive DRO kits and consoles from China. While the former are generally well made, albeit expensive, the main appeal of the Chinese models is low cost. Ebay and AliExpress are full of two and three axis DRO kits from Chinese sellers for under $500; the cost from an established reseller will be 1.5-2 times as much. While the glass scales are generally pretty decent, the consoles are the place where the manufacturers cut corners by using low quality generic parts, cheap membrane keypads, suboptimal manufacturing processes and poor quality control. With proper setup and care such DROs can be pretty accurate, but since the warranty service offered by Chinese sellers is unreliable at best, you should factor in the cost of replacement console if the original one fails.

LCD Based DROs

Digital readout consoles that use LCDs to display the readouts are relatively newcomers to the market and instead of the 7-segment display they use graphical LCDs to display the information. This design has several benefits. First of all, it can display numbers, and especially text, in a more readable format. Second, it can display reacher information that includes graphics and other elements. Finally, the display can adapt to the task at hand, making the menu system simpler and more intuitive. LCD based DRO market segment is still mostly dominated by the high-end units from well known brands such as Heidenhain, Newall, Acu-Rite, Fagor. These are modern top-of-the line digital readouts built to last, offer many advanced features, and are a pleasure to use.They use either good quality mechanical or tactile membrane switches rated for hundreds of thousands of actuations in order to guarantee long service life, etc. The downside is that these features aren't cheap, and you should expect to pay at least $2000 for a mid-range DRO kit, and as much as $5000 for a high-end setup. Moreover, many of these manufacturers use proprietary scale protocols, especially in their higher end units, so if something fails out of warranty, the repair or replacement won't be cheap.

Over the last few years, some of the better known import manufacturers, such Aikron, Ditorn, etc. have introduced LCD based DROs that look very reasonable on paper and have very atractive price. Some even come with touchscreens. As is often the case however, lower price comes at the cost of quality and reliability, and complete duds are not that uncommon. When buying an import DRO, it's important to choose a reputable reseller that has a support center in your country and will help you deal with any warranty issues.

Tablet Based Touchscreen DROs

There are currently two tablet-based DRO systems on the market - TouchDRO and Acu-Rite DROpwr. TouchDRO was the first DRO designed specifically for a tablet, originally released in 2012. It runs on Android tablets. Acu-Rite DROpwr was released in 2022 and uses Apple iPad tablets.

Tablet-based DROs use a purpose-built scale interface adapter that reads the position data from the scales communicates wirelessly with the application on the tablet.

Tablet based DROs have many advantage over traditional DROs. First of all, Android tablets are readily available in a variety of sizes and form factors. They are relatively inexpensive, and have much more powerful hardware than any traditional DRO. As a result, TouchDRO can perform much more complex tasks, and is able to automate many manual operations.

Second, a tablet based DRO can leverage the convenience of multi-touch color screen, offering much more intuitive

user interface. The DRO is much easier to learn, and very convenient to use.

Finally, tablet based DROs offer a lot of flexibility. In particular, TouchDRO is not tied to a specific brand of DRO scales or tablets. As a result, it allows your to pick your preferred tablet size, select scales that fit your particular machine, and fully customize the user interface.

3. Dust Protection

A digital readout will be used in a relatively hostile environment of a machine shop and will be constantly subjected to dust and grime. In order to survive in such environment, a DRO needs to have some level of protection. If flood coolant is to be used routinely it's helpful to have at least IP65 level of protection, or better yet IP67 or IP68. Otherwise avoiding DROs that have cooling fans, open vents and mechanical switches is a good idea.

4. Vibration and Shock Resistance

This is often overlooked, but an average DRO will be subjected to severe vibration during machining. Unless the circuit inside is manufactured with vibration resiliency in mind, it is guaranteed to fail rather quickly due to a cracked solder joint. Most reputable manufacturers use precisely controller processes to ensure good mechanical strength, but this is often not the case with cheap Chinese units.

5. Keypad Switch Durability

Most traditional DROs use membrane keypads or mechanical switches for input. Quality of switches is measured in actuations, i.e. the number of times a switch can be pressed before it fails. Top-of-the line switches can be rated at millions of actuations, while cheap non-name membrane switches can fail after only hundreds of actuations. This information is generally not provided by the DRO manufacturers, so it's important to research keypad failure rates for the specific model you are considering.

6. Linear Error Compensation

Linear error compensation is arguably the most important function of a DRO. Without it you will not be able to calibrate the scales on the machine and the readout will always be off by some amount. There are two reasons for this. First, it's virtually impossible to mount the scale perfectly parallel, so there will always be a small amount of cosine error. Second, scales have manufacturing errors that are usually linear in nature. A DRO that lacks this function should not be considered to be a precision instrument and should be avoided.

Summary

Adding a DRO to a milling machine or a lathe can be a significant investment. Your budget will likely be one of the deciding factors, but it's important to keep in mind accuracy, reliability, usability, and overall interface design. There are top-of-the-line DROs that get high marks in all of these categories. They are usually very expensive and are out of reach for most hobbyists and small shops.

As is often the case, you will need to find a compromise between price, quality, and features:

- Basic 7-segment DROs from China come with a very attractive price tag. They also come with a lot of tradeoffs. DROs with 7-segment LED displays are hard to use, and their quality is usually rather poor. Worse yet, since these DROs are based on very old hardware design, they can skip encoder pulses and introduce rounding errors. In this day and age, these DROs are not worth the money, no matter how cheap they are.

- LCD-based Chinese DRO models are more user-friendly and are relatively affordable. Their biggest issues are poor quality control. There are many off-brand units that now sell for under $200. Those units use very basic low-grade hardware with buggy software and poor quality control. DROs from known Chinese brands, such as Ditron, Aikron, and Sino are much better, but some functionality is still pretty slow and clunky, and the clarity and brightness of the LCD screens is not great. Overall, an LCD DRO is not a bad choice for a hobby machine shop, as long as you are willing to tolerate some rough edges and don't expect the unit to last you for a decade.

- Consoles from well-known DRO brands, like Newall, Acu-Rite, Mitutoyo, etc. offer excellent quality. The biggest tradeoff is the high price tag. Even the most basic entry-level models from these brands cost 3-5 times more than Chinese DROs, and their full-featured high-end models often cost many thousands of dollars. Those DROs are not intended for hobby shops. Their target audience includes large professional machine shops that require NIST-traceable calibration certificates, on-site support, etc.

- Tablet-based DROs offer a good balance between quality and price, and offer features and ease of use that traditional console-based DROs can't match. TouchDRO, in particular, is a flexible DRO system that can be used with many different scale brands and types, works with a wide variety of Android tablets, and overall offers excellent value for your money. If you are a hobby machinist or a small machine shop owner looking for a professional-grade DRO for a reasonable price, TouchDRO might be a good option for you.