Differences Between Capacitive Scales

At first glance, capacitive linear scales look similar to one another, but a close look will quickly reveal that there is a bewildering array of models that use different data formats, communication protocol, wiring scheme, supply voltage, and refresh rates. It is therefore important to understand what the various differences are and how they impact the scale's compatibility and suitability for a DIY digital readout.

Encoder Type

At the heart of every scale lies the encoder that is used to determine scale position. All encoders fall into one of two categories: absolute and incremental. Absolute encoder is analogous to a tape measure that has markings next to each division, so to know a particular measurement you don't need to see anything but the current mark. Incremental encoder, on the other hand, has no markings, just the divisions. In order to get a particular measurement, you'd need to count the number of divisions from the beginning of the tape. In other words, an absolute encoder reads position, while an incremental encoder reads distance. This distinction, while subtle, has a huge implication: absolute scales don't lose their position when the power is lost, while incremental ones reset to zero at power-up.

At the time of this writing, the overwhelming majority of linear capacitive scales use incremental encoder with the exception of iGaging Absolute DRO Plus and a few Mitutoyo models (the latter are not supported by TouchDRO). Many other sellers advertise their scales as "Absolute", but it's just a misleading marketing tactic since the scales merely behave similarly to absolute scales by the encoder being powered up even when the display is off.

Data Format

The data format is the "language" used by the particular scales to send the data to their display unit or data dongle. Even though internally the scales represent the position as a simple positive or negative number, the manufacturers, for a number of reasons, use more complex data formats to transmit the position. At the time of this writing, the majority of Chinese scales use one of the following data formats:

- Sylvac 48-bit was developed in the '90s by a company called Sylvac to use with their digital scales. At some point, the format was reverse engineered and used by some Chinese scale manufacturers. The data is sent as a set of two 24-bit streams, one containing the raw position, and another the same position with display settings applied (units, incremental offset, etc.)

- BIN 6 is a simple data format that was first adopted by the inexpensive digital caliper manufacturers, but now is frequently used by Shahe and other modern 3V scales. This format uses a single 24-bit stream that is broken up into six 4-bit nibbles. Some of those nibbles contain the position in binary format, while others contain flag bits that denote selected units, incremental mode, etc. Notably, there are several "dialects" of this format that differ in the position of the flag bits.

- BCD 7 (Binary Coded Digital) uses seven 4-bit nibbles, but instead of encoding the position in binary format, where each nibble represents a number from 0-15, BCD 7 uses 6 nibbles to represent 6 decimal digits (0-9) and one to denote the sign, units, and the position of the decimal point. In essence, the data stream represents the contents of the LCD display using 28 bits of data. This format used to be rather prevalent, but as of the last few years, has all but disappeared from the inexpensive Chinese scales.

- iGaging 21-bit format is used by current iGaging EZ-View DRO scales and their iGaging DigiMag predecessors. It's the simplest format that represents the raw position as a 21-bit two's complement number with the least significant bit coming first and the last bit representing the sign.

- iGaging Absolute format is heavily inspired by the Mitutoyo Digimatic SPC format with a few notable omissions. As implemented by iGaging, this format is more like a 52-bit version of BIN6 format since it doesn't use any of the special bits.

It's important to keep in mind that most manufacturers don't advertise their data format for competitive reasons, while others require licensing fees, etc. Furthermore, manufacturers often introduce small tweaks to lock in the users into their ecosystem.

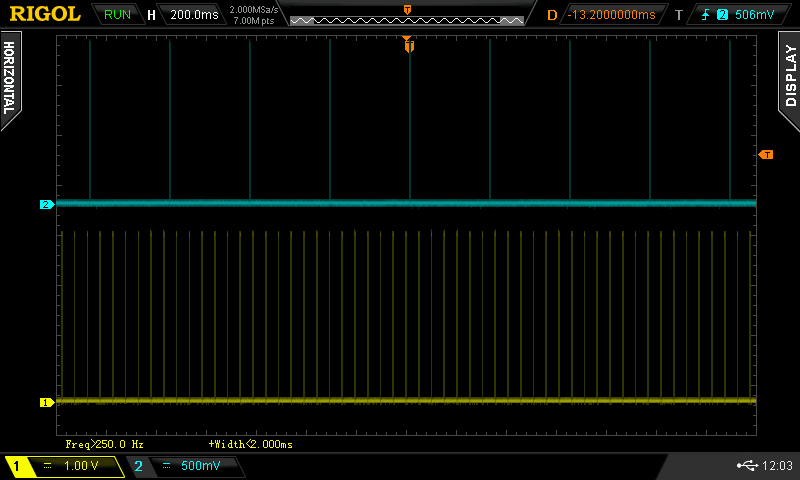

Communication Protocol

Communication protocol defines how the bits are sent across the wire. With very few exceptions, capacitive linear scales use relatively simple synchronous communication protocol where one line is used to provide clock and another to send the data bits. There are subtle differences though. For example, iGaging 21-bit scales use a protocol where the display is the master, and thus, provides the clock signal. In contrast, virtually all other scales provide their own clock signal. One notable exception is Mitutoyo scales that use a 5-pin connector with an additional "Req" line. Mitutoyo scales still provide their own data clock signal, but the receiver has to use the "Req" line to request the scale to transmit data.

Another thing to be aware of is the fact that some scales require either the data line, clock line or both to be pulled up and/or down in order to initiate the data stream. This is the case with some newer Shahe scales, for instance.

Refresh Rate

The position refresh rate is another important consideration since it determines how responsive the DRO will be. Unfortunately, this is another parameter that is not advertised by the manufacturers. Inexpensive Chinese digital calipers and older Chinese linear scales have a refresh rate of 3-5Hz. In contrast, the refresh rate of the iGaging EZ-View scales is determined by the display unit (or TouchDRO adapter) and can be as high as 50 Hz.

Notably, some better Sylvac clones implement a "fast" mode that can be turned on by manipulating the data and clock line when the scale powers up. While there is no standard refresh rate in the "fast" mode, some scales go up to 50Hz or so.

Power Off Behavior

Most capacitive scales have a built-in screen timeout function to save battery. That in of itself is not an issue, but the problem is that many older Chinese linear scales and most inexpensive digital calipers stop data stream as well. Even worse, the majority of cheap calipers subsequently reset the position to zero. Since there is no reliable way to prevent or reset the timeout, these scales are not suitable for use with a DRO and should be avoided.

Frame Material

Traditionally, digital scales used hardened and ground stainless steel frame and machined stainless steel reading head housing often with copper gibs and some sort of gib adjustment. iGaging DigiMag was the first mainstream scales to use extruded aluminum frame and extrusion molded plastic reading head housing.

The scales above (iGaging DigiMag and Shars Digital Stainless Steel Machine Scale) are based on the same encoder, and differ only in the frame construction. All things being equal, stainless steel scales are inherently more accurate since the interface between the frame and the reading head is much more rigid and precise, and stainless steel has a much lower coefficient of thermal expansion. Furthermore, plastic rubbing on the oxidized aluminum surface will eventually be abraded away, resulting in a sloppy fit and loss of repeatability. In practice though, when the scales are rigidly mounted to a cast iron machine, the shortcomings of the aluminum scales are mostly negated. Given that stainless steel scales are two or more times more expensive than similar aluminum scales, aluminum scales offer a good value for the money.

Power Supply Voltage

Most capacitive scales use either 1.5V or 3V power supply. This has a few important implications for use with a multi-axis DRO setup. First and foremost, connecting 1.5V scales to 3V supply will permanently damage them. Moreover, a 1.5V signal is too low for a microcontroller that runs at 3.3V, necessitating some sort of amplifier circuit. Finally, many 1.5V scales have their frames connected to the positive side of the battery, while most 3V scales have it connected to the negative side. This makes mixing and matching 1.5V and 3V scales problematic.