Lathe Tool Offset Memory Basics

Tool Offset Memory (also called Tool Library) is used to pre-program and subsequently recall positions of commonly used cutters. This feature greatly speeds up the turning process and reduces the chance for human error.

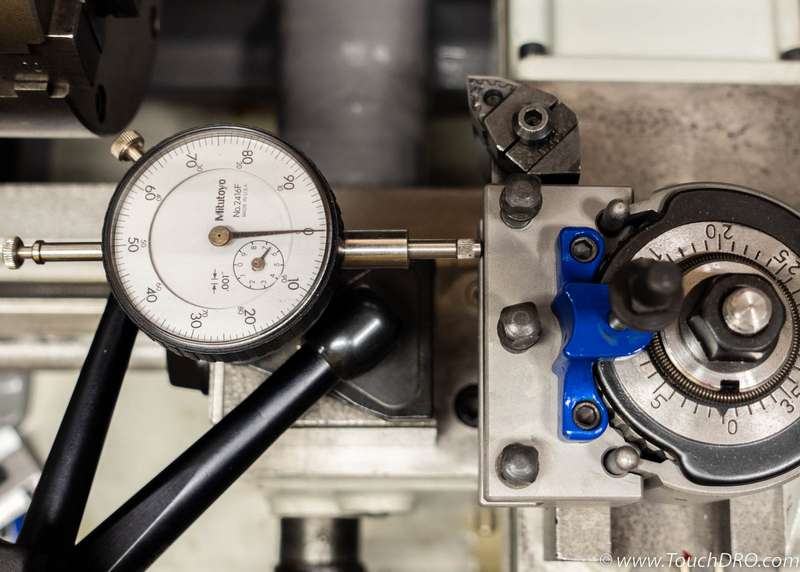

To be able to use the Tool Offset Memory and related features, your lathe should be equipped with a repeatable quick change tool post. Although it's more practical to use Tool Offset Memory with indexable insert tool holders, TouchDRO offers a convenient way to use this feature with a mix of tooling.

Basic Concepts

Tool Offset Memory is often one of the least understood and underutilized features of a Digital Readout. Unfortunately, the clunky and un-intuitive user interface of a traditional Digital Readout often discourages the machinists from using the Tool Offset Memory. In contrast, TouchDRO offers a simple and convenient user interface that makes programming and using tool offsets very straightforward.

While turning a part on a manual lathe, you often need to use a few different cutters. For instance, the process might look as follows:

- Use a roughing cutter to quickly hog off material and get the part close to the final dimension

- Switch to a finishing tool for the last few lighter passed to get major OD features to final dimension

- Switch to a grooving tool to cut OD grooves, etc.

- Use to boring bar to machine ID features

- Finally, use a cutoff tool to cut the part off

Each time you switch the tool, you need to re-establish the coordinate system, either by taking a test cut and measuring the diameter, or touching off the tool to the surface and re-entering the previous dimension into the DRO. The obvious reason for that is that these cutters have different stick out and left-to-right offset, so their cutting edges are not in the same position. In other words, the cutting edges are offset in relation to each other.

If your lathe is equipped with a quick change tool post, those offsets are constant as long as the tool stays mounted in its dedicated cutter, and the angle of the tool post doesn't change. The idea behind the Tool Offset Memory is to store these offsets into TouchDRO's memory, so you can simply re-call them when swapping the tool.

How Does it Work

When you recall a tool from TouchDRO's Tool Offset Memory, the application does some basic arithmetic under the hood. The process is similar to this:

- When you start machining the part, you select the roughing cutter from the list. In other words, you are telling TouchDRO that you are about to use a cutter (that has some arbitrary offsets) to take the first cut

- You then take the first facing cut. Without changing the cross slide position, you can now measure the resulting diameter and enter it into TouchDRO as the X axis readout.

- The application now knows that, taking into account some tool offset, the diameter of the part is N

- When you swap the tool, you can select the new tool from the list.

- TouchDRO will load the offset for the new tool, subtract the old tool offset and adjust the dimension.

Requirements

In order to use the Tool Offset Memory, you need to have a way to reliably re-insert the cutter so that its cutting edge position stays unchanged. In practice, this likely means the following:

- The lathe should be equipped with a "quick change" tool post

- Each stored tool should have a dedicated tool holder. The tool should either not be removed from the holder, or there should be a way to re-mount it in the same exact position

- The angle and the height of the tool holder in relation to the lathes axis of rotation should remain the same as it was when the tool was entered into memory

The use of compound slides is a point of confusion. Some resources on the Internet suggest that the compound slide should be completely removed, or the Tool Offset Memory would be rendered useless. This is not true with TouchDRO. While replacing the compound slide with a solid mounting block can be beneficial for machine rigidity, it has no bearing on the Tool Offset Memory as long as the slide is not moved while using TouchDRO and the angle of the tool post is not altered.

A common approach is to set the tool post to a known angle by indicating a flat side of a tool holder before programming or using a given cutter. It's very likely that the majority of your cutters are held either perpendicular or parallel to the axis of rotation. If any tools are held at an angle, they can be programmed and used at a predefined angle that is set using an angle block or a sine bar.

Finally, if you routinely use hand shaped and sharpened HSS cutters, you can either re-program the offset each time you alter the edge, use a jig to re-mount the tool with the edge in the same position, or simply omit storing offsets for the tool into memory.

Summary

Lathe Tool Offset Memory can be a very useful feature on a lathe that is equipped with a quick change tool post, even when the machine is routinely used with a mix of indexable insert tooling and hand-ground HSS cutters. The user interface for programming and using tool offsets is quick and intuitive. In practice, there are only three requirements for the tools programmed into the Tool Offset Memory.

Contrary to a popular belief, the angle and the position of the compound slide is irrelevant, as long as the angle of the tool post is unchanged. If the compound slide is not tracked by the DRO, it should not be moved during machining for obvious reasons.